Laser Powder Bed Fusion

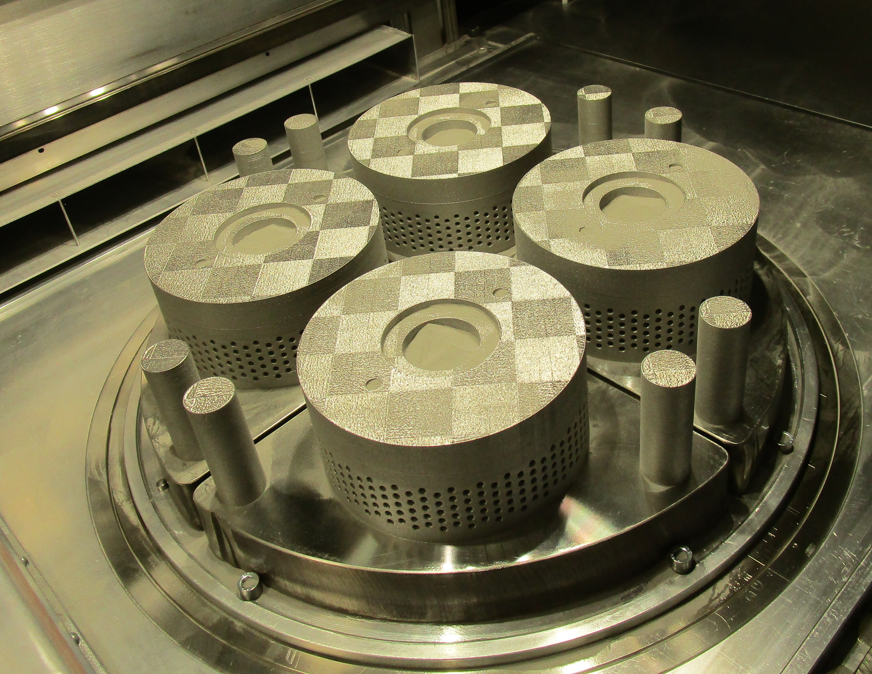

Laser Powder Bed Fusion (LPBF) is the advanced additive manufacturing process we use to produce high-performance metal parts — layer by layer — directly from digital designs. A thin layer of metal powder is spread across a build plate, then selectively melted by a high-power laser. This process repeats, layer after layer, until the final part is complete.

LPBF allows for exceptional accuracy, strength, and design freedom, making it ideal for components that require complex geometries, internal features, or high thermal and mechanical performance. At A3D, we use LPBF to manufacture parts for propulsion systems, energetic devices, and structural applications where performance and reliability are critical.

By consolidating multiple parts into a single printed component, LPBF reduces weight, assembly time, and failure points — making it a powerful force multiplier in both industry and defense applications.

Want to know whether LPBF is right for your part or project? Get in touch with our Perth-based team to explore what’s possible.