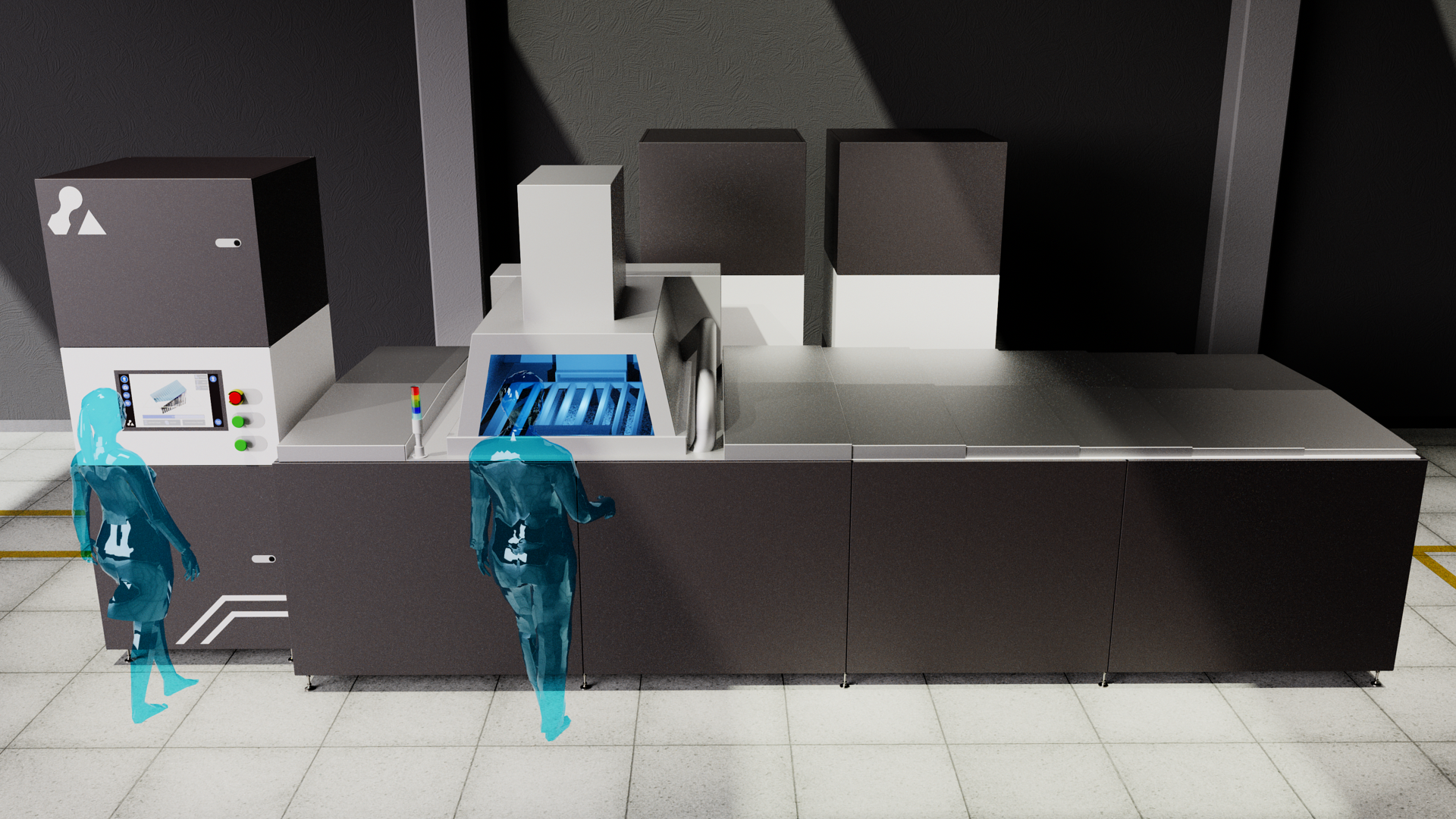

Printer Design and Manufacture

A3D’s additive manufacturing platform is built on a deep understanding of welding principles — adapted and optimised for high-performance metal 3D printing. Our process development draws on decades of proven metallurgy and fabrication practices, allowing us to refine laser parameters, motion systems, and gas flow control to achieve outstanding part quality and repeatability.

What sets our systems apart isn’t just power — it’s the way we control it.

Our 1500W laser systems deliver up to 50% more power than many LPBF printers on the market, but it’s the integration of optics, pre-planning algorithms, and advanced extraction systems that allows us to use this power effectively. Each subsystem is engineered to work in harmony — delivering deeper melts, higher build rates, and better mechanical outcomes across a wide range of alloys.

These capabilities are backed by a growing portfolio of patents, including:

- Multi Concurrent Printing (MCP) – enabling high-speed, time-offset printing strategies

- SHARP / MMP (Multi-Module Printing) – a scalable, flat-surface recoating architecture for large-format builds

- Directional and multi-layer powder deposition methods – designed to improve throughput and surface integrity

Our printer architecture reflects a deliberate shift: away from generic machine building, and toward solving real-world manufacturing challenges. From propulsion housings to energetic device components, A3D’s platform is designed to enable performance

Contact Us

Contact the team to find out more about Aurora’s unique 3D printers, their technology and how they could help your organisation.

For more about Aurora‘s printer design and manufacturing capabilities please reach out to a member of our Perth team.