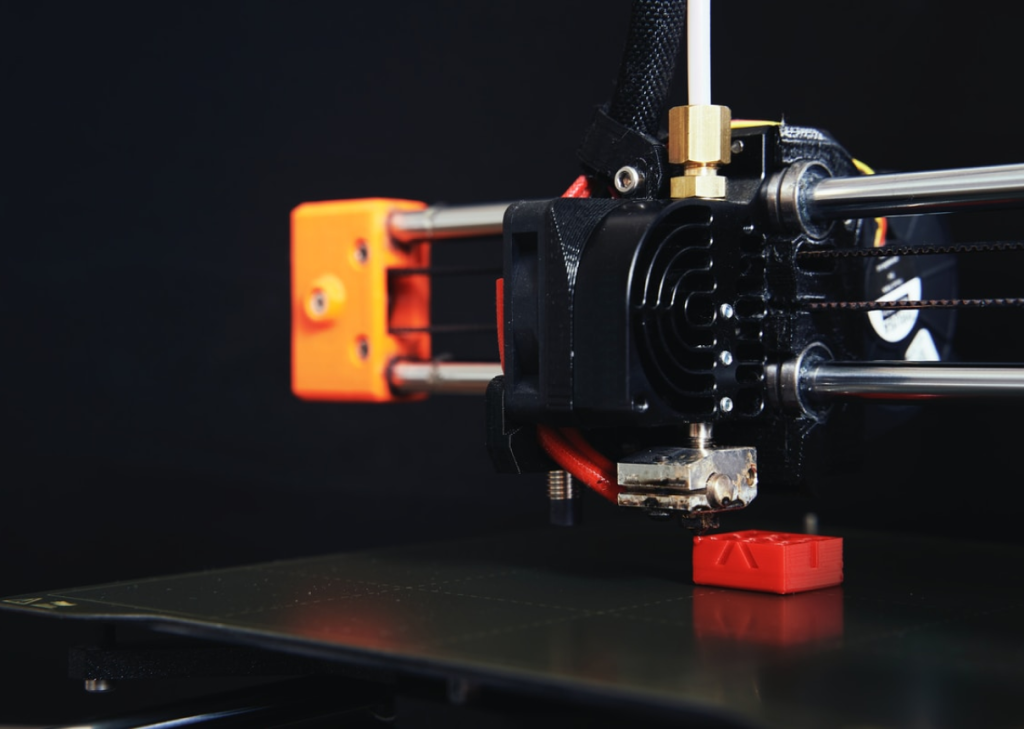

Material Extrusion – FDM

Material extrusion 3D printing services and technology uses a continuous filament of a thermoplastic material as a base material. The filament is fed from a coil, through a moving heated printer extruder head (extruder). The molten material is forced out of the extruder’s nozzle and is anchored onto a 3D printing platform, which can be heated for extra adhesion.

A wide variety of materials can be extruded, the most popular being thermoplastics, such as Acrylonitrile Butadiene Styrene (ABS), PolyLactic Acid (PLA), High-Impact Polystyrene (HIPS), Thermoplastic PolyUrethane (TPU), aliphatic PolyAmides (PA, also known as Nylon), and used more recently, high performance plastics such as PolyEther Ether Ketone (PEEK) or PolyEtherimide (PEI). If you are interested in our 3D printing services through high- temperature plastics, don’t hesitate to contact a member of the Aurora team.

Material Extrusion is just one of the ways in which we provide 3D printing services to the local Perth and global industries.